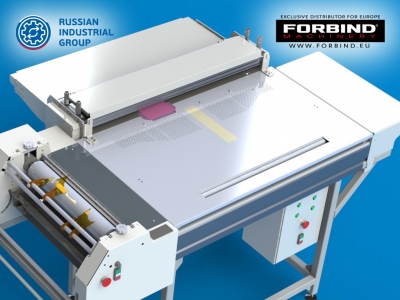

“OFFICER” – SEMI-AUTOMATIC HARDCOVER MAKING MACHINE

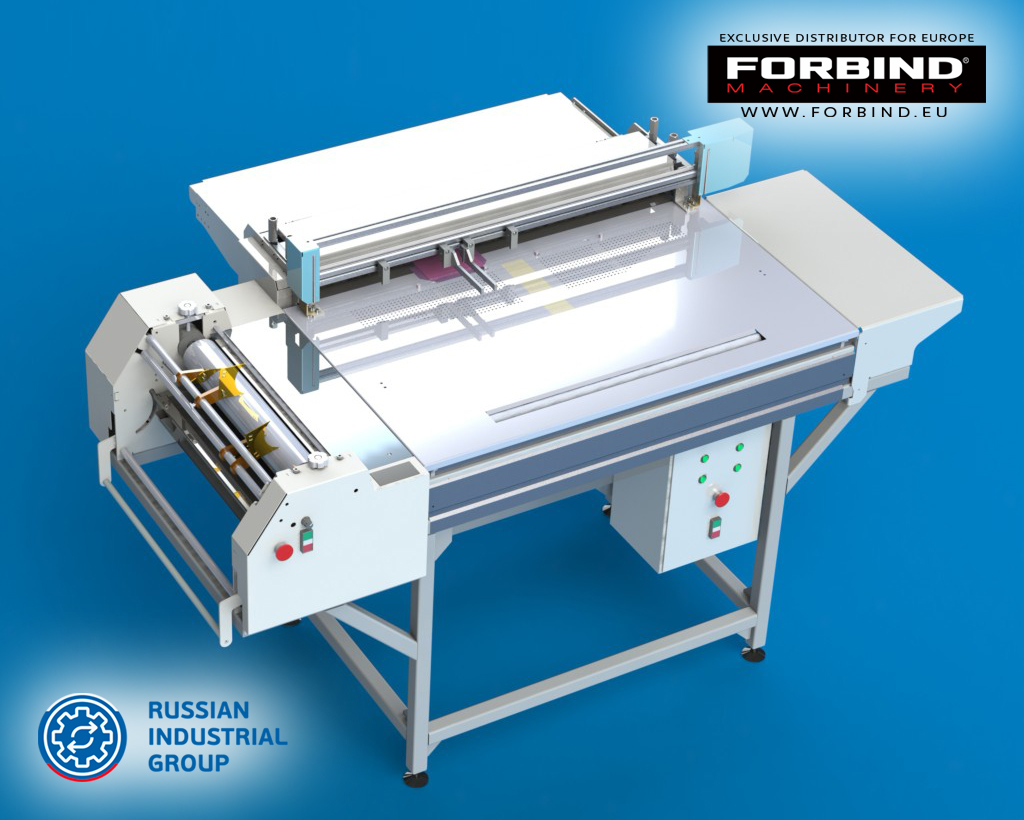

“Officer” is a highly automated example of a semi-automatic hardcover making machine. It has vastly enhanced capabilities compared to its competitors.

Distinctive feature is:

- extended max format (500x1000mm)

- the ability to work with min format (50x50mm)

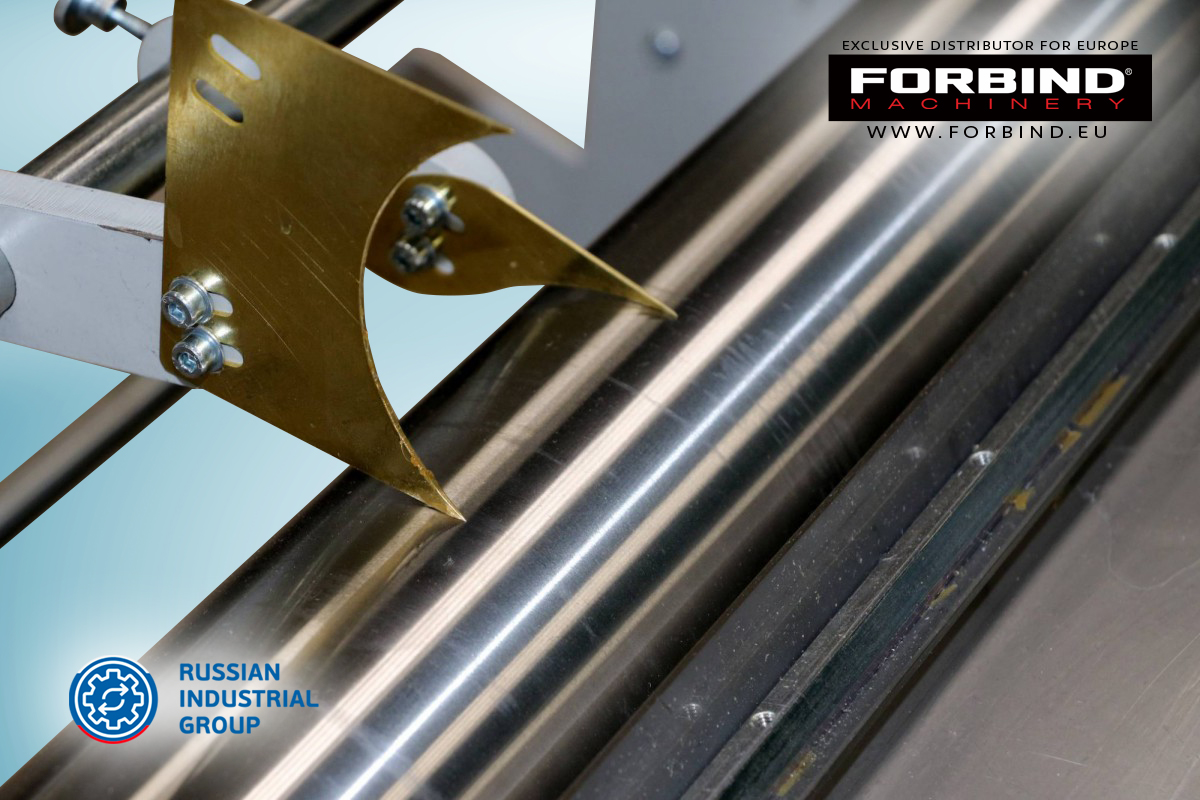

- torque adjustment when bending the edge

- the operator’s hands are freed (the liner and carton stops are controlled by electric pedals).

- adjusting the speed of the glue machine

- adjustable calendering speed (up to 1 m / s)

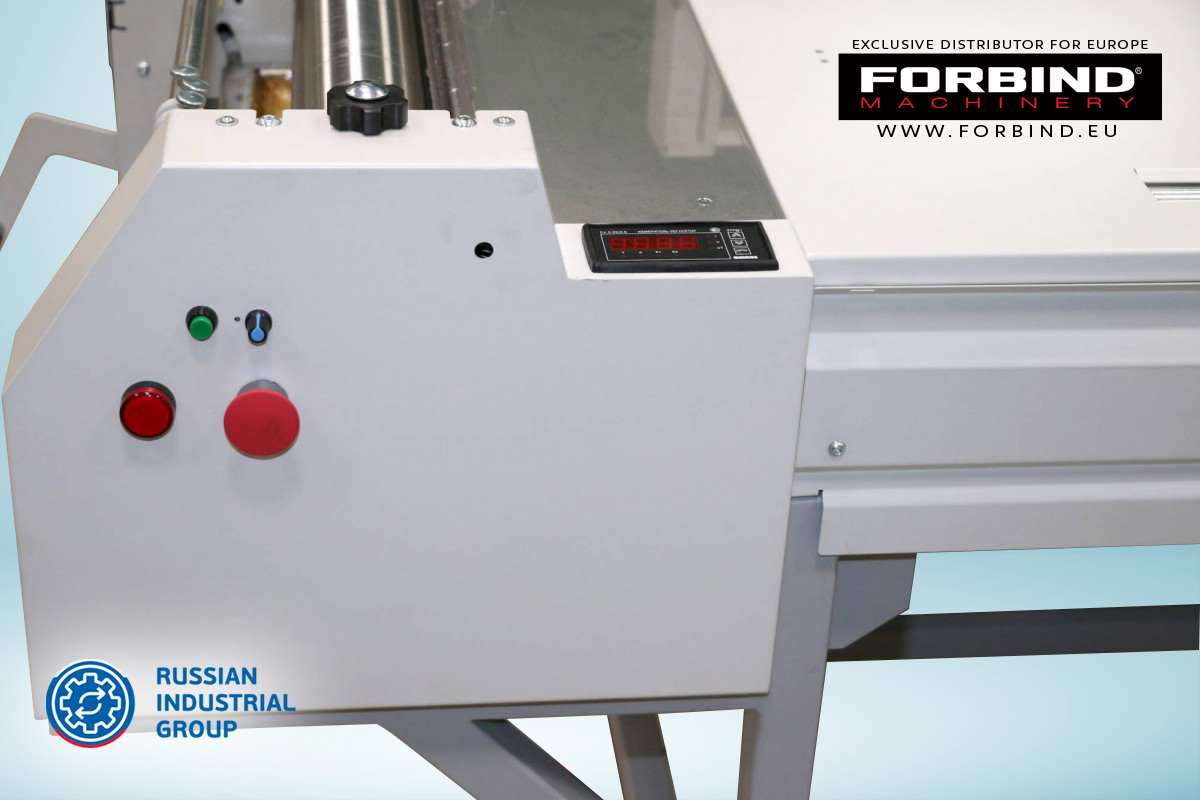

- machine power supply 220V

- no air supply required

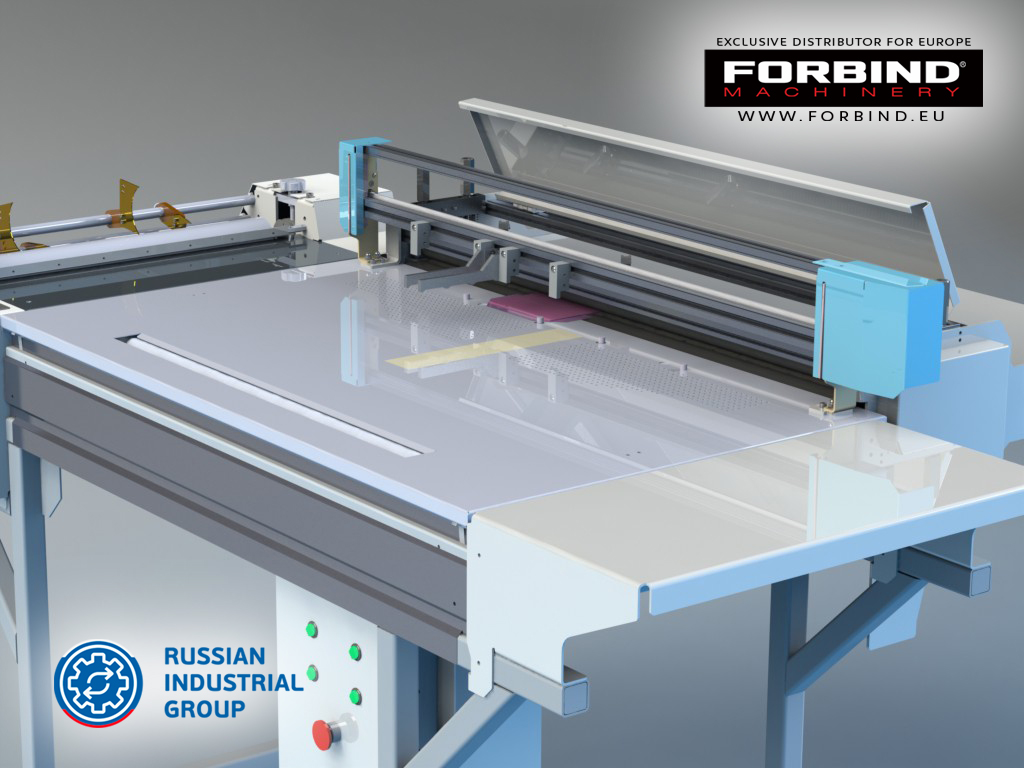

- built-in vacuum surface

- two-channel temperature control system (protects the adhesive from overheating and reduces water evaporation)

- Bath with re-return of water vapor in the adhesive up to 60% of the evaporation volume

The “Officer” machine works with all semi-rigid binding materials: lederin, balacron, bumvinyl, fabric vinyl (calico, lederin) vivela and others.

The machine is self-sufficient and does not require additional operating devices such as a compressor.

Working principle:

KDM Officer is a model for the principle of labour and ergonomics, which is very close to the polygraphists. The machine can make hardcover covers, diplomas, certificates, folders, inserts, as well as all types of lamination. It also allows you to work with small-format issues, e.g. student books, as well as large-format - folders, large-format books.

The operator takes the cover and submits it to the adhesive module, with pre-selected plates.

Purpose and choice of the plates

Depending on the plate, the operator receives the cover with the adhesive layer up or down. The operator then places the cover on the mounting table, pressing the pedal once to release the cardboard clamps, which in turn presses on the cover. After that he lays the cardboard on the cover. Releases the cardboard clamp pedal and depresses the pedal a second time (to control the cover clamps). At this time, the cardboard clamps are lifted and the cover clamps are released, which releases the hem folding and calendering module. The operator submits the sandwich on the cover in the module for automatic hemming and calendering. Folding is done in pairs.

KDM Officer is a model for the principle of labour and ergonomics, which is very close to the polygraphists. The machine can make hardcover covers, diplomas, certificates, folders, inserts, as well as all types of lamination. It also allows you to work with small-format issues, e.g. student books, as well as large-format - folders, large-format books.

The operator takes the cover and submits it to the adhesive module, with pre-selected plates.

Purpose and choice of the plates

Depending on the plate, the operator receives the cover with the adhesive layer up or down. The operator then places the cover on the mounting table, pressing the pedal once to release the cardboard clamps, which in turn presses on the cover. After that he lays the cardboard on the cover. Releases the cardboard clamp pedal and depresses the pedal a second time (to control the cover clamps). At this time, the cardboard clamps are lifted and the cover clamps are released, which releases the hem folding and calendering module. The operator submits the sandwich on the cover in the module for automatic hemming and calendering. Folding is done in pairs.

Depending on the selected mode, the hem folding machine pulls the finished cover either into the operator's hands or brings it to the back of the machine.

The “Officer” machine has the following key adjustments:

- calendering speed

- brush torque

- glue machine speed

- switching the speed of movement of the cardboard stops

- choice of output of finished products (to the operator or to the back of the machine)