KDM Kursant - a machine for making hardcover covers

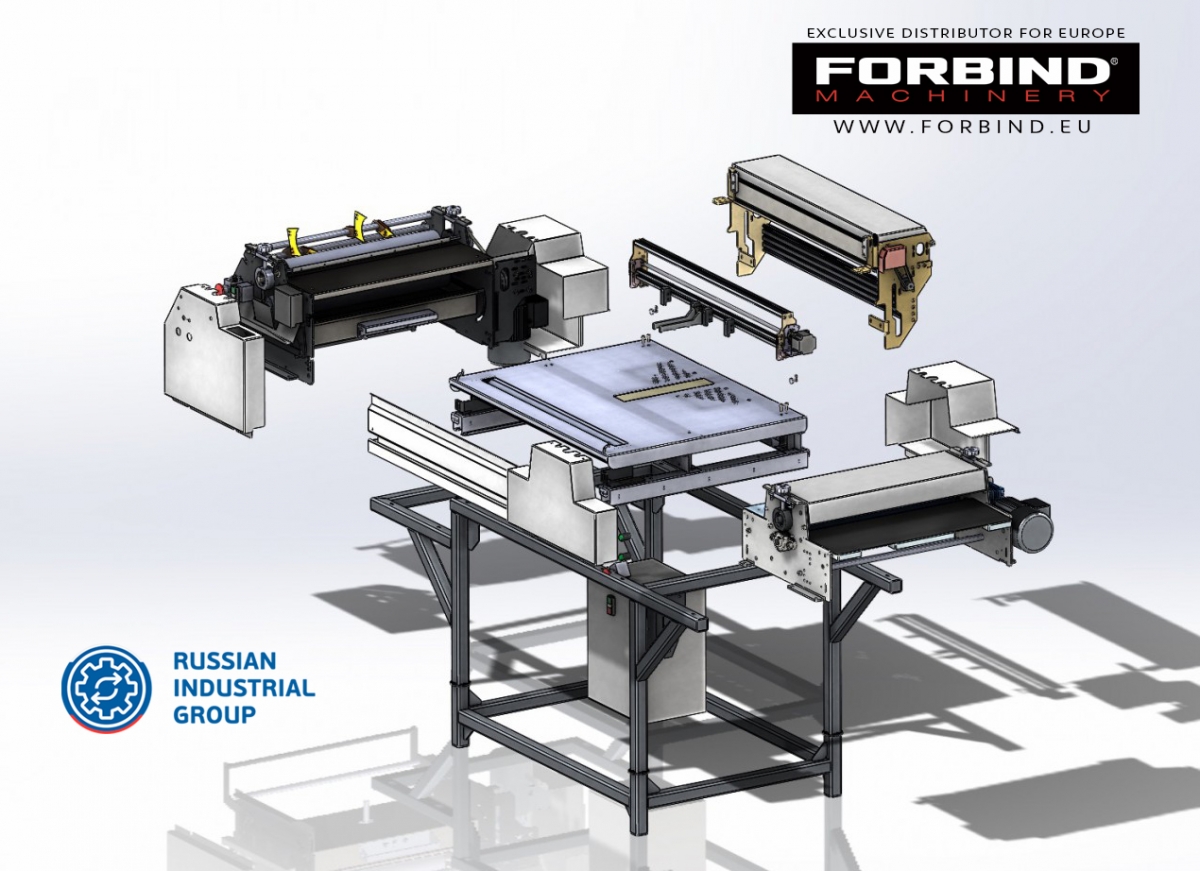

KDM Kursant is a semi-automatic machine for making hardcover covers with a high degree of automation and ergonomics.

KDM Kursant is designed for the production of small and medium issues, all types of lamination and hardcovers.

DESCRIPTION:

KDM Kursant has a high degree of automation and ergonomics:

- Automatic clamps on the glued material

- Automatic clamp on the cardboard

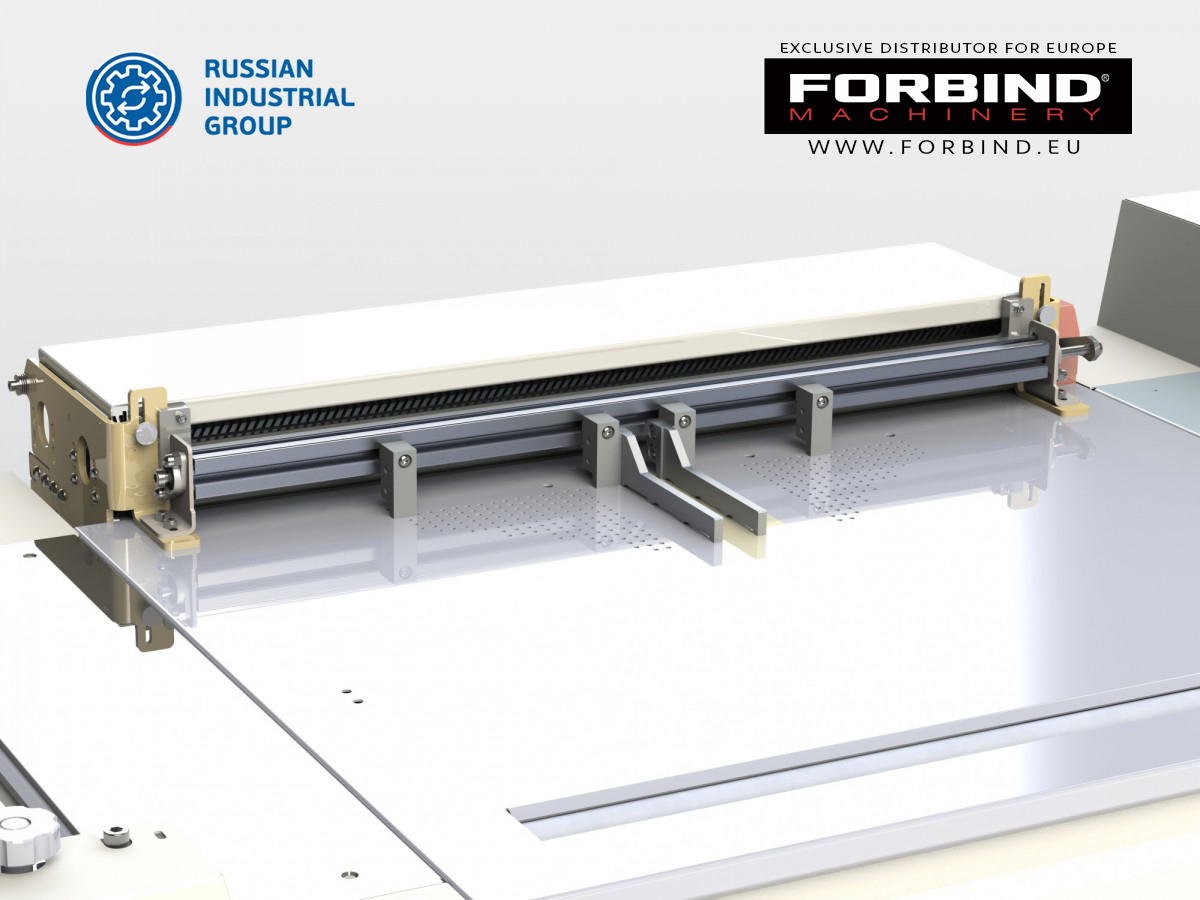

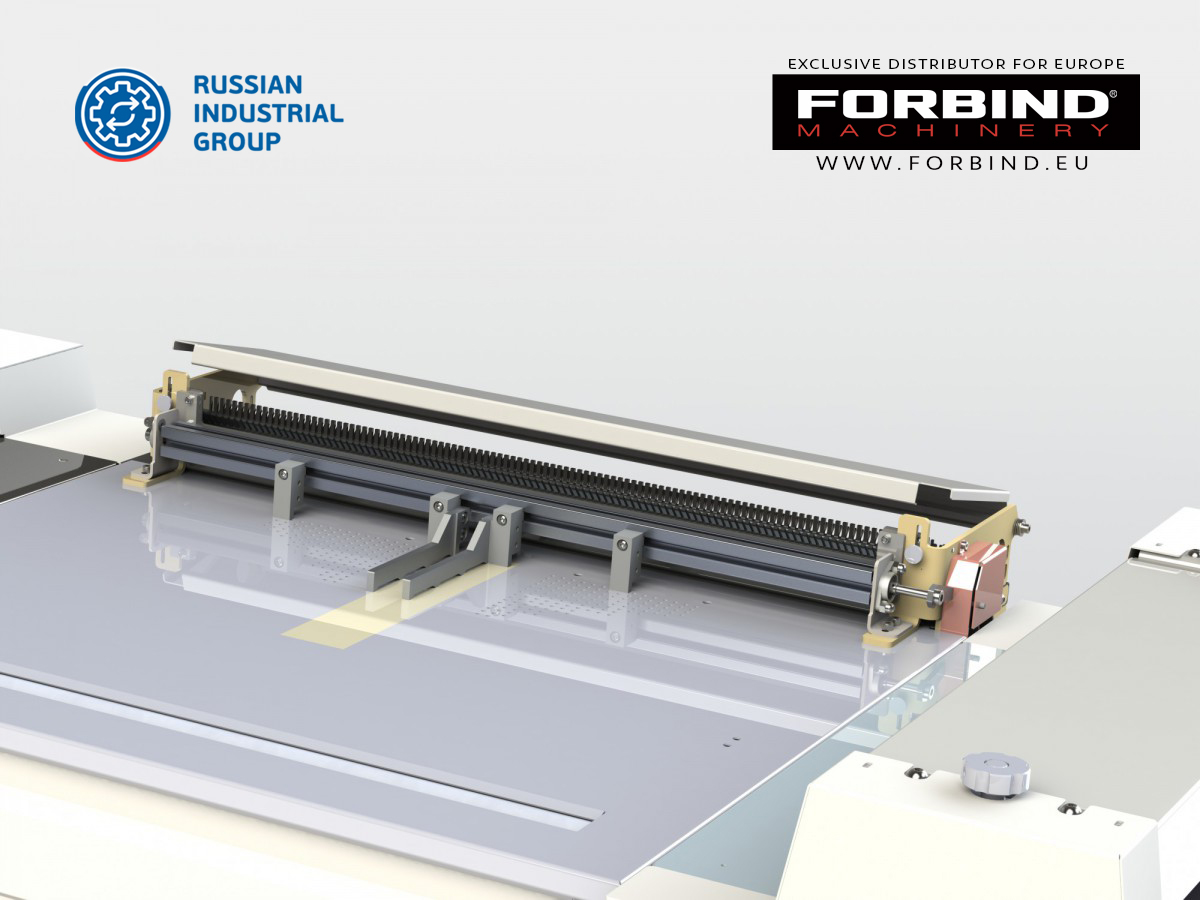

- Module for mechanical folding on the hem of the clothing (up to date for errors in cutting of the clothing, non-standard orders, small format issues)

- Automatic arrangement of the finished products (no time is lost for storage of the finished covers, it does not interfere with the operator when he takes the finished covers for subsequent actions)

- Regulation of the speed on the adhesive rollers (usually the operators work at a higher speed, but in the production of inserts, especially in small format products such as certificates, diplomas, etc. it is more convenient and the quality is better to work at low speed)

- Highlight positioning (important when working with digital prints where the clothing is printed on a digital machine)

- Equipped with guiding and converting plates (The converters are needed when the adhesive material has to be delivered with the adhesive layer up, the guiding plates are relevant when we have inserts, when it’s important for us to receive it with the adhesive layer down, eg certificates, diplomas, etc.)

KDM Kursant is made so that the operator constantly monitors the quality of production at high perfomance, which is ensured by the ergonomics of the processes.

The power supply is 220 in single-phase, with power when heating the glue 2 kW.

The machine can be positioned in an office.

When using Bricol glue, manufactured by OOO "KleyZhelatinProm" https://www.kleyjelatin.ru/, there is no need for additional aspiration, there isn’t any unpleasant odors.

After finishing work, cleaning the machine takes 1-2 minutes.

All these advantages of KDM Kursant provide high productivity, reduce errors and fatigue of the operator, the time for servicing the machine is minimal (preparation of the issue takes 1-2 minutes, cleaning takes 1-2 minutes)

Protection systems:

- System for protection of the adhesive rollers from injury in case of foreign objects

- System for protection of the collars of the adhesive rollers from bending (for example when winding the clothing on the roller or for foreign objects: keys, bolts, watches, towels, etc.)

- Technology for protection of the surfaces of the calender rollers

- Technology for protecting the machine from electric shock.

Principle of work:

Hardcover covers, diplomas, certificates, folders, inserts, as well as all types of lamination can be made on the machine.

The principle of operation of KDM Kursant is similar to the equipment from other manufacturers, but there are significant differences.

The operator takes the cover and supplies it to the adhesive module, with pre-selected plates.

- Turning plates are used where it is necessary to turn the adhesive side up (covers, diplomas, certificates, etc.)

- Guide plates are used where the adhesive needs to be down (inserts in diplomas, certificates, folders, etc.)

Taking the glued cover, the operator puts it on the mounting table after pressing the pedal firsthand.

When pressing the pedal, the clamps for the cardboard are lifted, the cover is placed under them and the pedal is released. The cover cardboard is placed on the cover (it can be plywood, foam board, plastic, metal, glass, etc.). The operator then presses the other pedal, which releases the cover clamps, and then the first pedal, which releases both the cover and the cardboard. The operator then puts the workpiece into the hem folding module. By folding one hem, the module returns the workpiece back, and the operator puts it on the other side and so on consecutively from all unfolded sides. As the calendaring of the cover is carried out at the final stage, the processing time of the cover is shortened, and after that it is immediately displayed in the receiving compartment. The operator constantly monitors the quality of production as all operations are performed in front of him.

The reception system (tiers), the lighting of the assembly table, the electronic control of the processes, the constant convenient visual control, allows the attainment of high ergonomics of the process, which leads to high production